As part of my MIT application, I decided to showcase my hobby of hand crafting functional miniature skateboards. With the help of my friend and excellent videographer Marlon Dubois, I condensed the entire process of building one of these completely from scratch.

The video showcases 3d design, wood veneer inlay and molded lamination, metal machining, Low temperature alloy spin casting, cast epoxy, and micro scale assembly. I developed a lot of my molds, tools, and techniques the first time for this video to push my engineering and fabrication capabilities as far as possible. While it wasn't the most polished result, I'm so proud of the process.

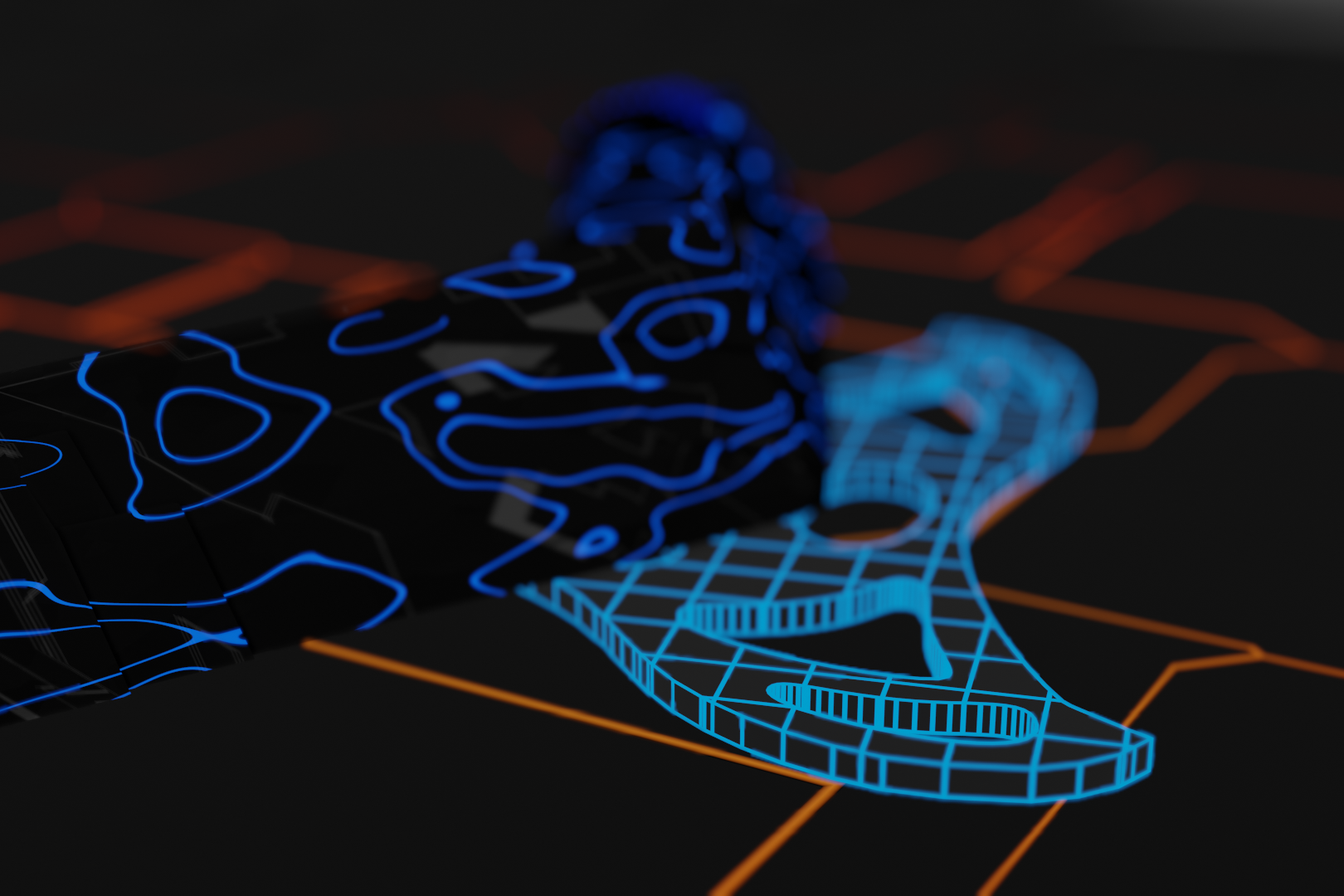

I first modeled the skateboard form scratch in SOLIDWORKS

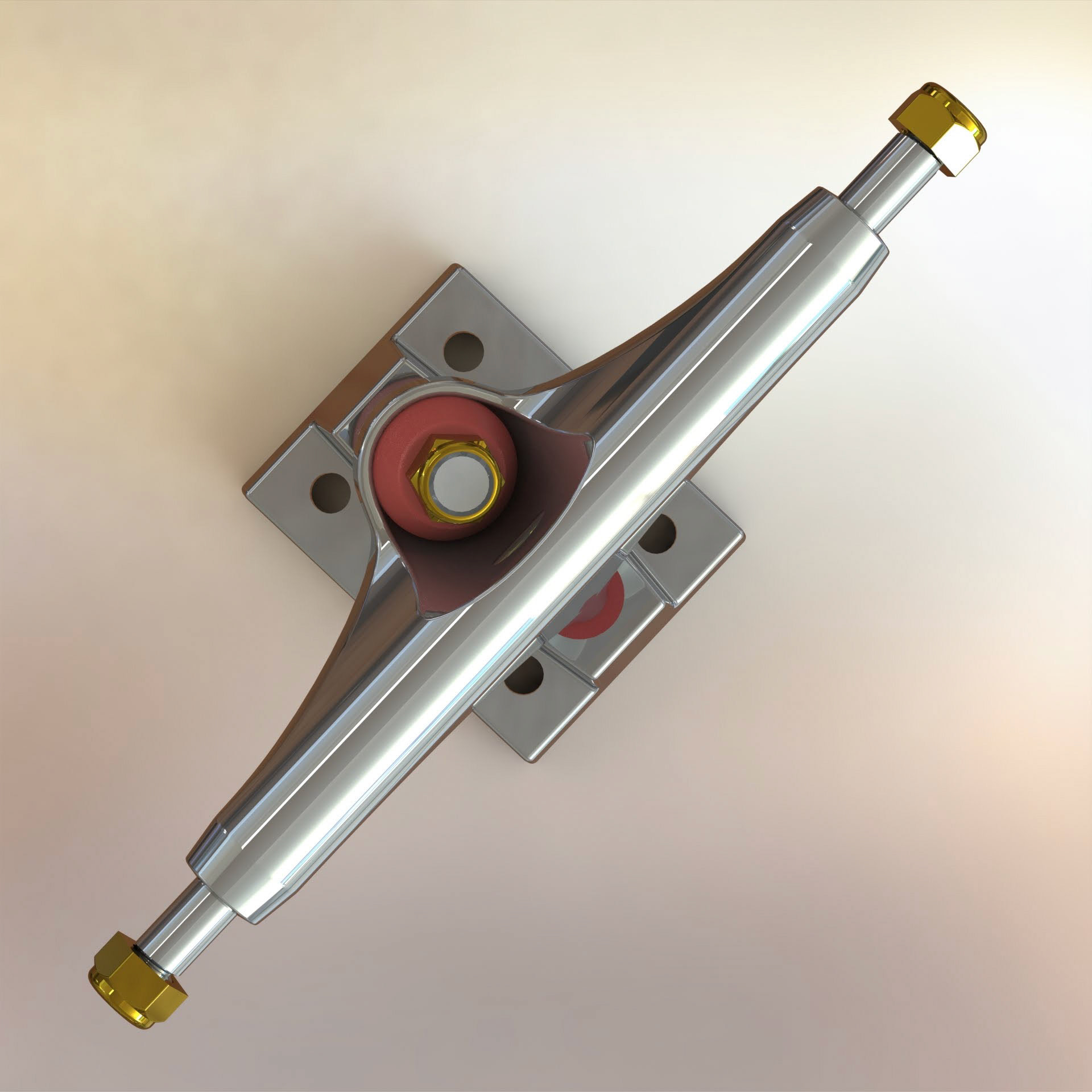

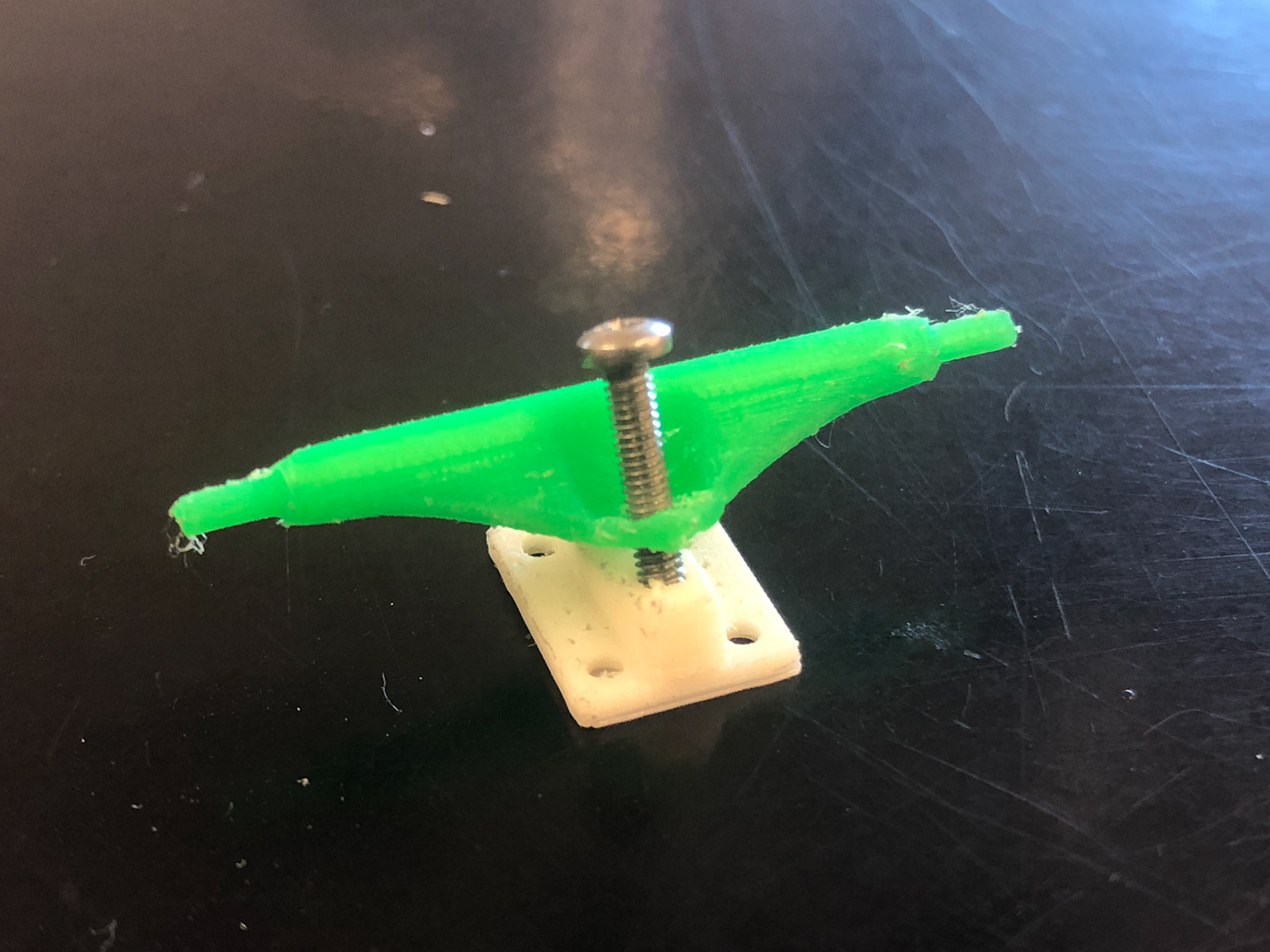

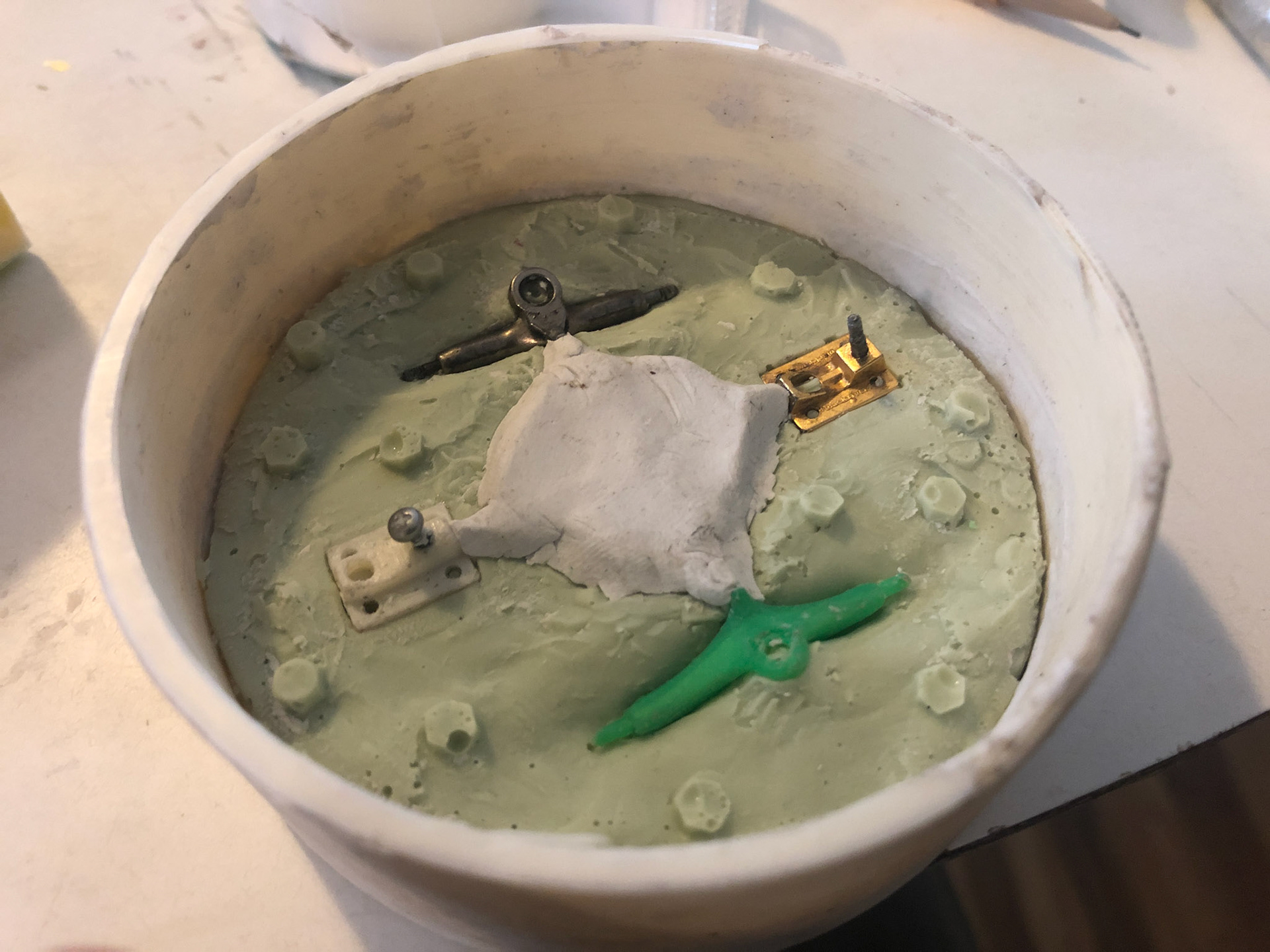

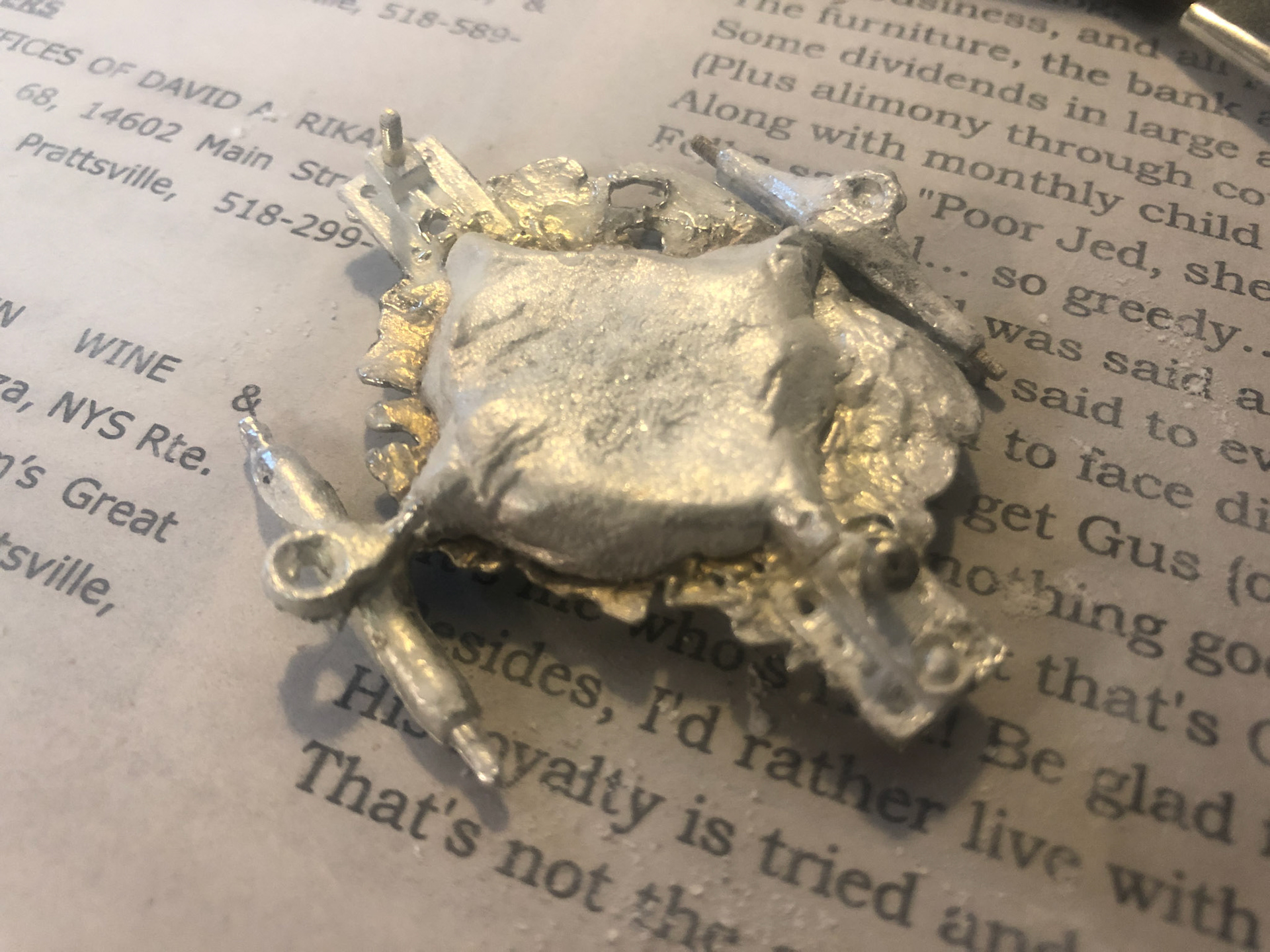

I refined the design of the trucks, and 3d printed positives, which I used to cast into a high temperature silicone disk mold

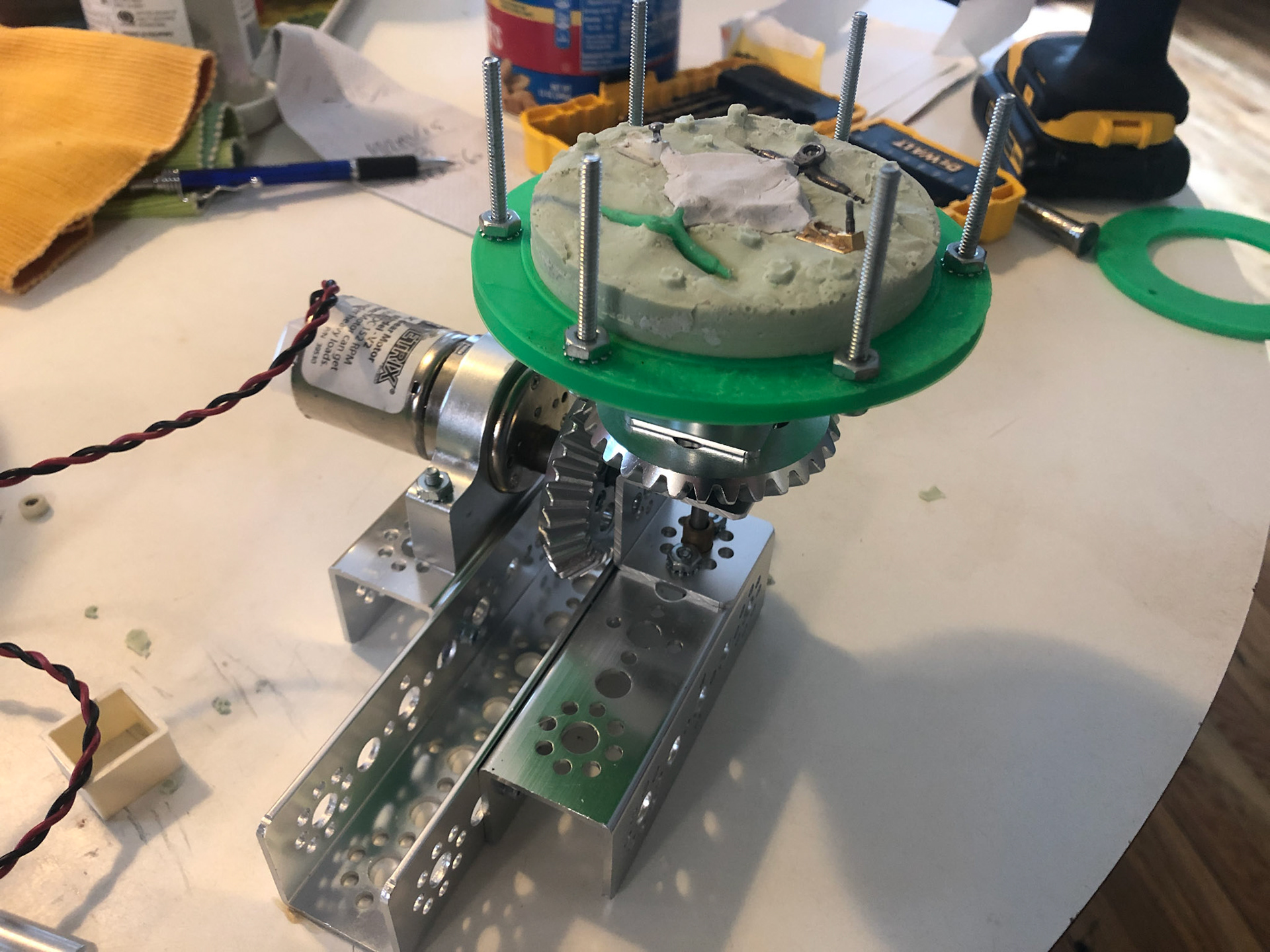

I built a spin caster to use centripetal acceleration to assist the flow of metal into the small mold cavities. I melted a non leaded Low temperature alloy on the stove top and poured it into a preheated spinning mold

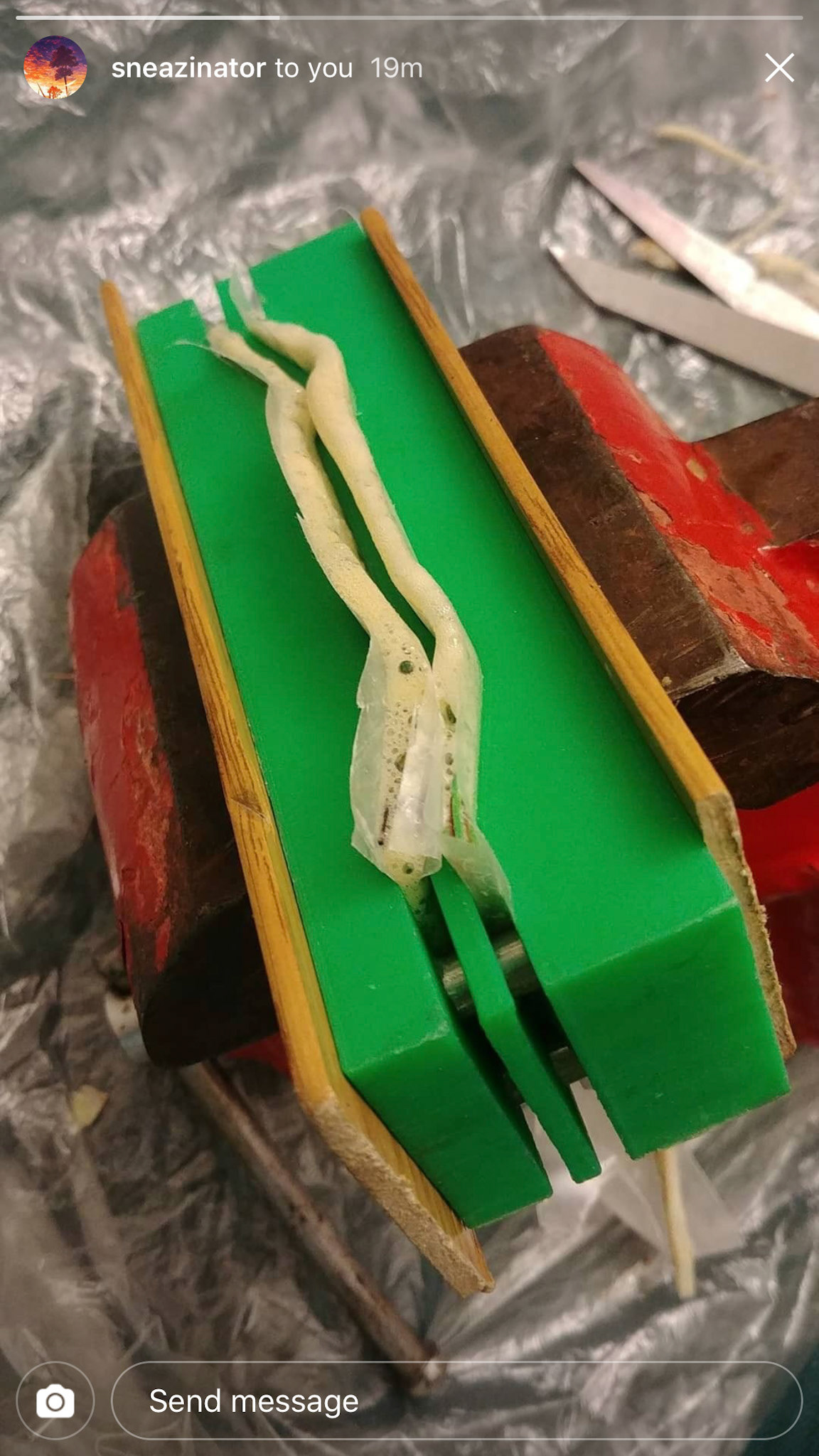

To create the skateboard deck, I pressed 5 layers of thin wood veneer and glue in a custom designed 3D printed mold. The geometry of the mold creates the same nose, tail, and concave that makes full sized skateboards strong and functional.